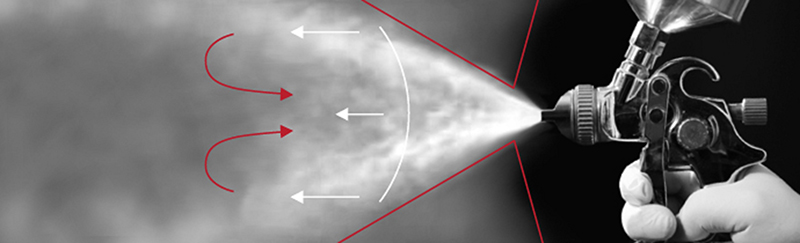

Regular compressed air has an extremely low temperature when it exits the spray gun, This, and air contaminations such as water and water damp, result in the paint having a high dewpoint. As a result, a lot of energy is required to cure the paint after application. Moreover, the whole object must be heated instead of just the repair surface. This ultimately results in wasted energy.

When exiting the spray gun, the cold compressed air interacts with the warm air of the environment. This results in turbulance and overspray. In order to get a decent paint layer the pressure needs to be increased with all consequences.

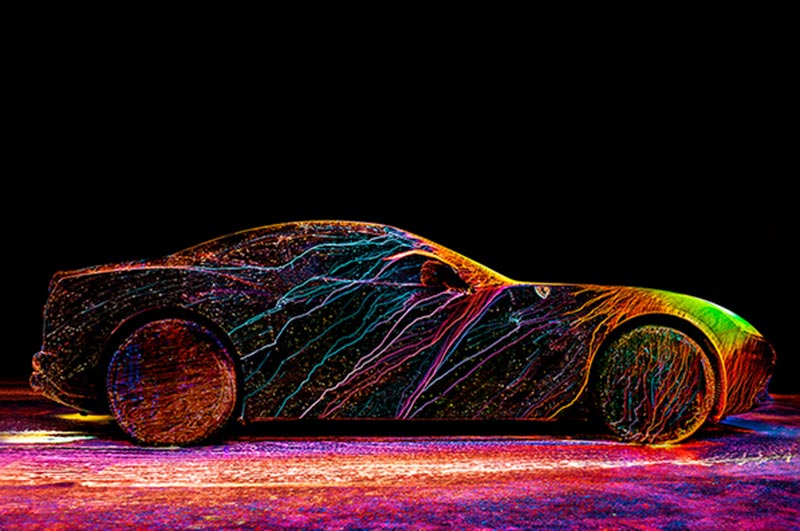

TEQ-Spray uses modulated High-Speed-Gas. This gas is compeletely free of any kind of contamination and does not attract any dust particles. In the tube no static charge is generated as a consequence of the friction between the gas and the tube. As a result, a fully electical neutral gas is generated, which is an optimal base for paint application. Additionally, the gas is heated. This causes the speed at the gun nozzle to approximately double! Ultimately these properties enable a reduction of the spray gun pressure resulting in the following advantages:

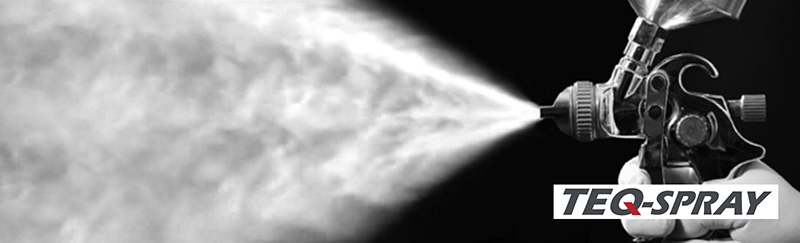

The difference between TEQ-Spray and standard compressed air can be seen in the images below:

In the first image generation of overspray and turbulence are shown, spraying with normal compressed air. The third image shows a more homogenous spray pattern. A comparison of TEQ-Spray and regular ompressed air is shown in the middle image.

The paint pressure would be reduced with approximately 25% while maintaining the same exiting speed as with regular compressed air.

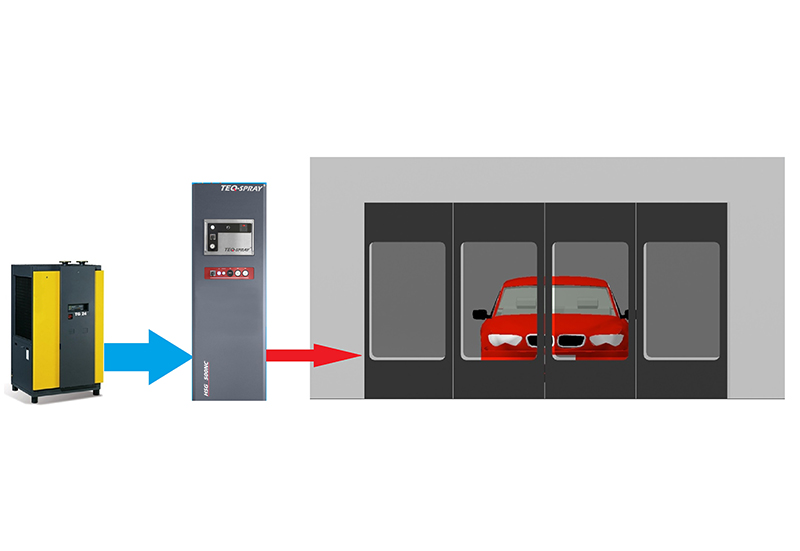

TEQ-Spray is available as a plug-in system. The system can easily be incorporated between the compressor and the spray booth. The existing paint tube and an additional filterset can be removed. The new heated paint tube goes directly from the control unit into the spray booth.

Would you like more information or obtain a tailor made quotation?

We are happy to handle your request!

The High-Speed-Gas is forwarded to the control unit from the tank.

Inside the control unit, an unique control system is installed. The system keeps the temperature stable. The maximum temperature accuracy is ± 0.5 0C! The system keeps the temperature stable during the entire paint cycle. Because no water vapor is left in the carrying gas, paint jobs will have the same characteristics irrespective of the weather and environmental conditions. Combined with the anti-static property of the carrying gas, you will have a perfect base for wet paint application!

Just like the highest quality is demanded of paint jobs, we aim for the same degree of quality for the system.

That’s why TEQ-Spray is built only from the best material and components, all produced in Germany and the Netherlands.

The system complies with the latest and highest requirements.

The use of high-quality materials makes the system extremely reliable and requires only a minimum of maintenance. Depending on the system and application, maintenance takes place after 1 or 2 years and/or 2.000 operating hours. Maintenance remains limited to replacing a filter road, similar to the systems currently in the babins, but they will be phased out.