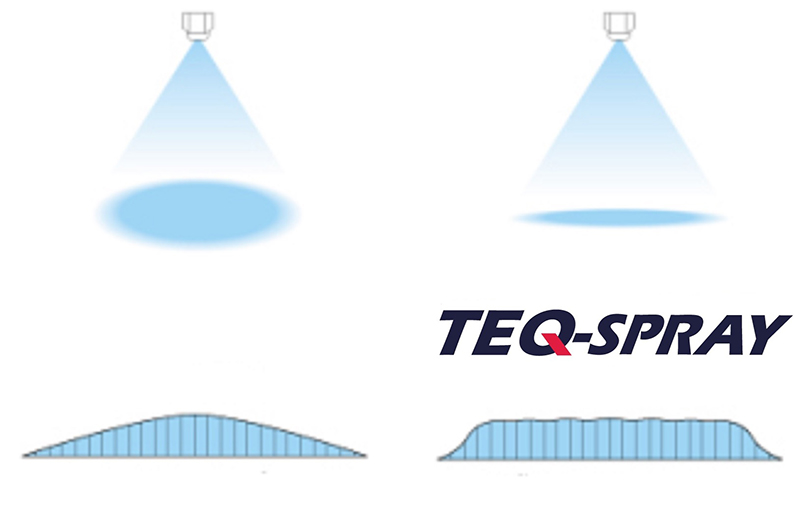

By using High-Speed-Gas, the outflow velocity at the paint gun is approximately 50% faster than with regular compressed air. Because of this we can – and have to – reduce the pressure at the gun, with the advantage that less overspray is generated. In general, the pressure will be reduced with approximately 25%.

Instead of a lot of overspray, much more paint material is transferred to the object. This means that number sweeps can be reduced while obtaining the same layer thickness!

The absolute minimum of paint saving we can guarantee is 15%. In practice a reduction of 20-25% occur more often, some customers have even achieved a reduction in paint material of more than 35%!

TEQ-Spray generates far less overspray, so less paint will be wasted on booth walls and the filters. Less booth maintenance is required, filters will last longer and the booth will have less down time.

Would you like more information or obtain a tailor made quotation?

We are happy to handle your request!

Because TEQ-Spray generates much less spray mist, less paint material ends up on the walls and in the floor filters.

The cabin requires less maintenance and the filters last longer. The cabin has less gridlock because of cleaning work.