The High-Speed-Gas assures a much better atomization. The characteristics of the gas contribute to less overspray and turbulance. The result is increased opacity, which reduces the amount of layers required for the same thickness.

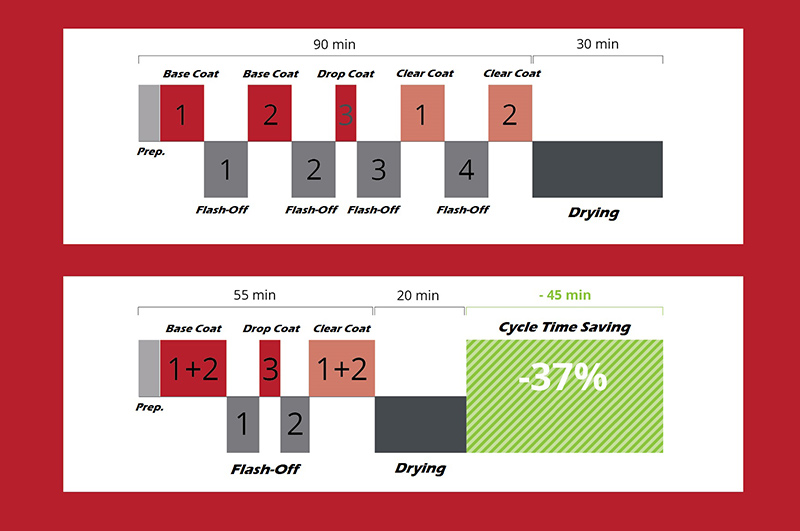

Due to the need for fewer layers, which dry even faster due to the heating, the entire painting cycle is much shorter. Depending on the paint trade and the paint variety, a saving of up to 50% can be achieved here!

Would you like more information or obtain a tailor made quotation?

We are happy to handle your request!

Independent of your paint brand and -system.

Whether you spray paint using Sikkens, Cromax, Spies-Hecker, Standox, Glasurit, RM, Nexa, PPG, Lesonal, Lecher, de Beer of Valspar, you will achieve a variety of benefits using TEQ-Spray.

When using paint systems where the base coat is applied with several layers – with intermediate heating -, the benefit will be, that combined coating of the several layers can be achieved without intermediate heating!

Systems where the drop coat is applied with the wet surface of the first base coat, the advantage will be a reduced halo effect, faster drying and ommission of the blender.

For both systems the duration of application is significantly shorter, as a consequence of a more homogeneous and consistent spray pattern. Coupled with the reduction in the baking cycle, the total paint cycle can be decreased up to 50%!

Application of the clear coat is even possible with a single layer, without compromising to the thickness!